Automation

Battery Production Line

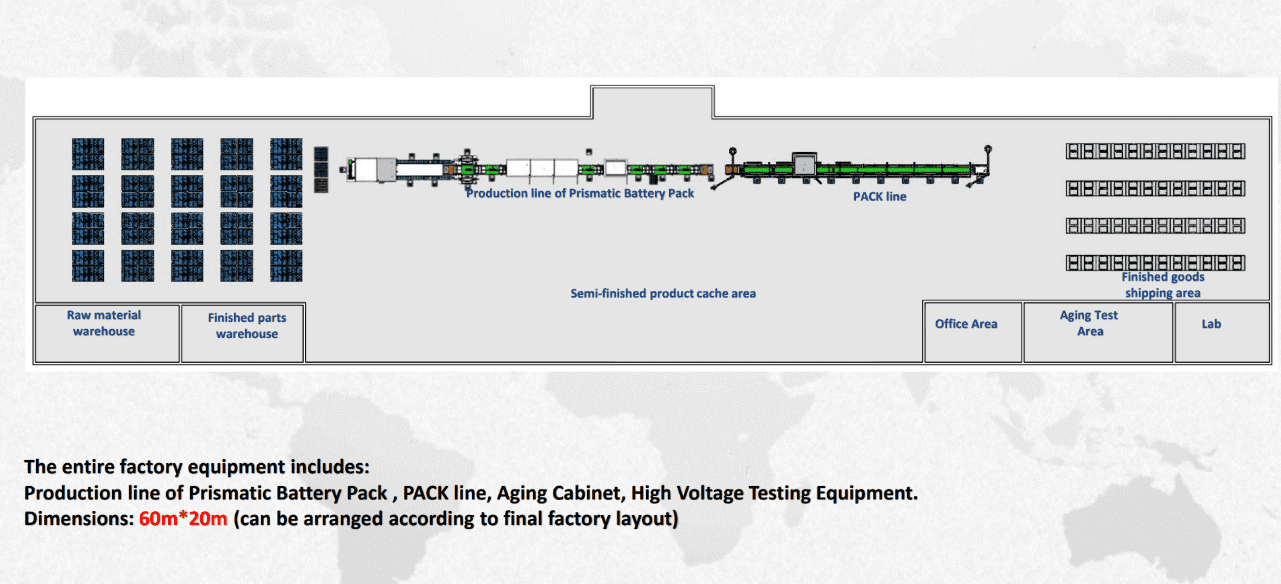

It has automatic intelligent assembly production from square aluminum shell

to module and then to PACK box, which improves product quality consistency,

automation level and reduces manual intervention. It realizes intelligent data

management for the entire production process and process parameters of the

product.

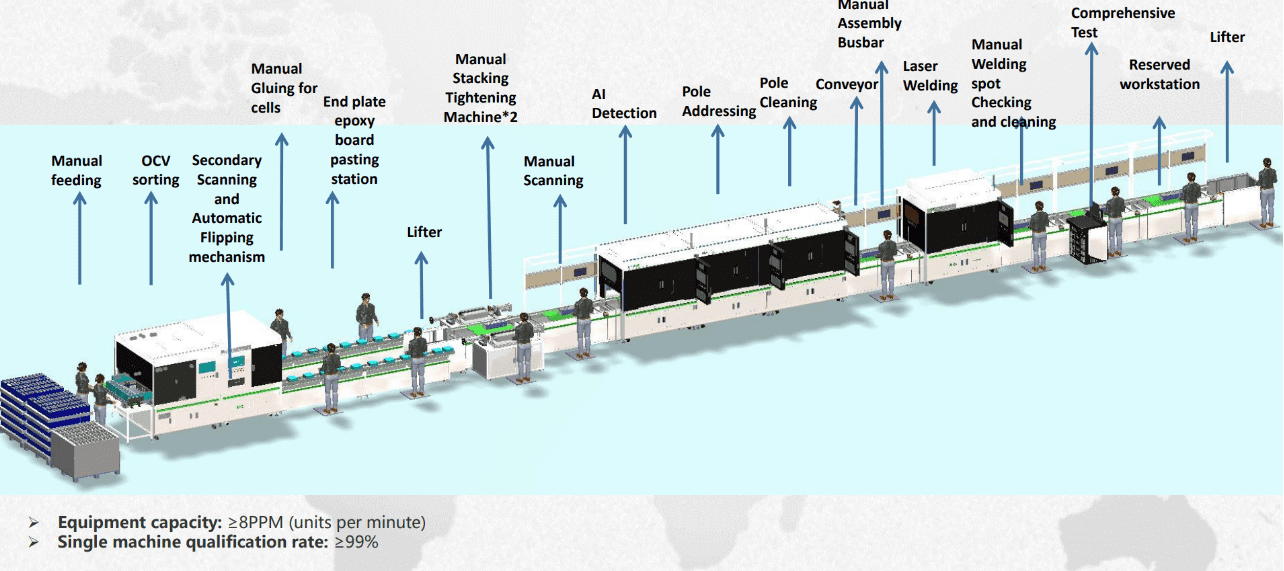

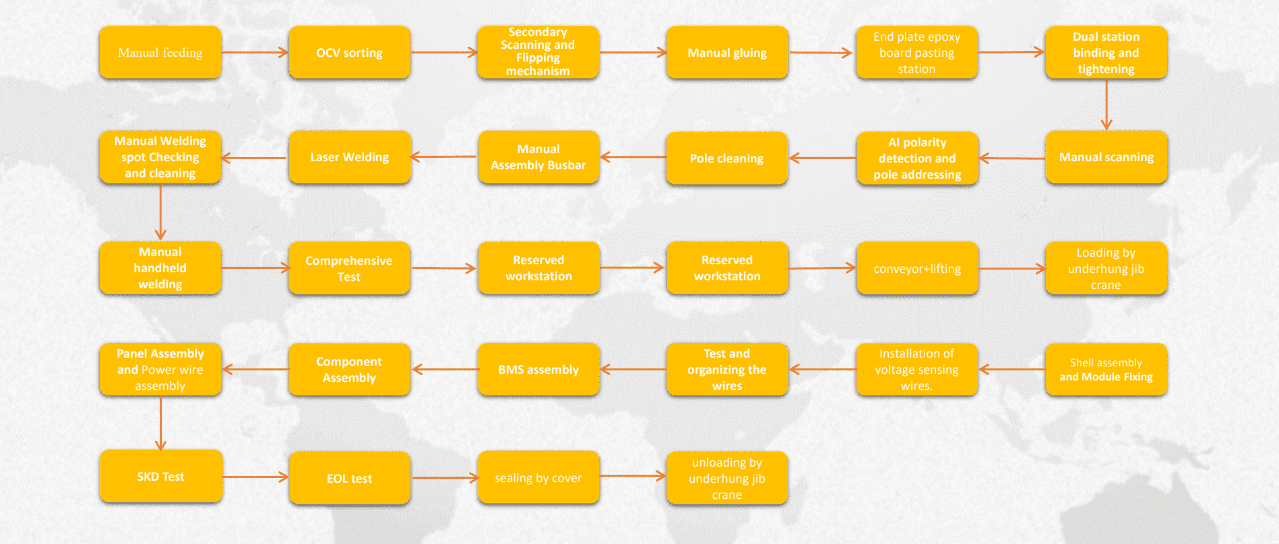

Including battery loading and unloading, cell scanning code, OCV, thickness

detection, cell automatic coating, cell automatic cleaning, glue coating and

pre-stacking function, module end plate and separator automatic feeding and

coating, battery core stacking, module leveling and pre-compacting, module

pressing and automatic tying, module end plate coding;

Scan code data binding, module BUSBAR pre-weld CCD positioning and cell polarity

detection, harness integration board installation, BUSBAR automatic compression

and soldering, module withstand voltage and insulation detection, module robot

blanking and die assembly PACK box, module cache line, PACK empty box feeding

automatic conveying line, PACK box automatic conveying line, module connecting

piece welding, manual detecting roller line, lower line and whole line MES

system and other working units.

Send Message

WE OFFER BEST IN CLASS SERVICE FOR YOUR NEEDS

86-13631354535

-

Message